Pultruded gratings are available in the major types of resin: isophthalic (moderate chemical corrosion), vinylester (severe chemical corrosion) and phenolic (fire resistant), with slip-resistant surfaces for safety or smooth surfaces for food applications.

Però, EUROGRATE® pultruded gratings are manufactured using isophthalic, vinyl ester, or phenolic polyester resins with a synthetic protective surfacing veil. The high percentage of glass fibre in load-bearing bars provides a high strength to weight ratio and high longitudinal stiffness. Exceptional chemical and mechanical resistance.

EUROGRATE® aims to offer highly specialised products, supplying gratings designed specifically for use in areas of high fire risk requiring minimum smoke emission and maximum fire resistance.

More specifically EUROGRATE® offers pultruded gratings in phenolic resin that are approved by the US Coast Guard (USCG) with an L2 rating in compliance with the new ASTM F3059-15 standard.

They can be supplied in standard panel sizes:

- 914 x 5800 mm

- 1220 x 5800 mm

- or made to measure.

TECHNICAL CHARACTERISTICS OF PULTRUDED GRATINGS:

For technical documentation, contact EUROGRATE® by email at info@eurograte.com or fill in the online form

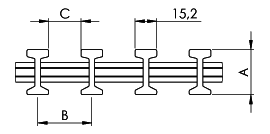

| Codice | Size "A" (mm) | Size "B" (mm) | Size "C" (mm) | % Open area | |

|---|---|---|---|---|---|

|

|||||

| GI-4010 | 25,4 | 25,4 | 10,2 | 40% | |

| GI-5010 | 30,4 | 15,2 | 50% | ||

| GI-6010 | 38,1 | 22,9 | 60% | ||

| GI-40125 | 31,7 | 25,4 | 10,2 | 40% | |

| GI-50125 | 30,4 | 15,2 | 50% | ||

| GI-60125 | 38,1 | 22,9 | 60% | ||

| GI-4015 | 38,1 | 25,4 | 10,2 | 40% | |

| GI-5015 | 30,4 | 15,2 | 50% | ||

| GI-6015 | 38,1 | 22,9 | 60% | ||

|

Connecting profiles centreline 152.40 mm |

|||||

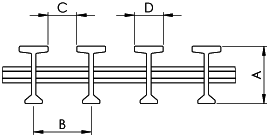

| Code | Size "A" (mm) | Size "B" (mm) | Size "C" (mm) | Size "D" (mm) | % Open area |

|---|---|---|---|---|---|

|

|||||

| GT-1210 | 25,4 | 43,4 | 5,3 | 38,1 | 12% |

| GT-1810 | 50,8 | 9,5 | 41,3 | 18% | |

| GT-2510 | 50,8 | 12,7 | 38,1 | 25% | |

| GT-3310 | 61,0 | 19,7 | 41,3 | 33% | |

| GT-3810 | 61,0 | 22,9 | 38,1 | 38% | |

| GT-1215 | 38,1 | 43,4 | 05,3 | 38,1 | 12% |

| GT-2515 | 50,8 | 12,7 | 38,1 | 25% | |

| GT-3815 | 61,0 | 22,9 | 38,1 | 38% | |

| GT-5015 | 50,8 | 25,4 | 25,4 | 50% | |

| GT-3320 | 50,8 | 38,1 | 12,7 | 25,4 | 33% |

| GT-5020 | 50,8 | 22,9 | 25,4 | 50% | |

|

Connecting profiles centreline 152.40 mm |

|||||

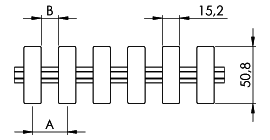

| Code | Size "A" (mm) | Size "B" (mm) | % Open area | ||

|---|---|---|---|---|---|

|

|||||

| GHL-4020 | 25,4 | 12,9 | 40% | ||

| GHL-5020 | 30,4 | 15,2 | 50% | ||

| GHL-6020 | 38,1 | 22,9 | 60% | ||

|

Connecting profiles centreline 152.40 mm |

|||||

EUROGRATE® pultruded gratings in phenolic resin are approved by the US Coast Guard (USCG) with an L2 rating in compliance with the new ASTM F3059-15 standard, guaranteeing excellent corrosion resistance, low smoke emission and high temperature and fire resistance.

USCG L2 phenolic pultruded gratings are certified to the following standards:

- Chemicals Sector

- Water Treatment Sector

- Construction and Civil Engineering Sector

- Electricity Sector

- Engineering Sector

- Marine Sector

- Oil & Gas Sector

- Transport Sector

EUROGRATE®: the experience of a manufacturer in business for over 40 years at your service.